CastFuse Material: Difference between revisions

Jump to navigation

Jump to search

(Created page with '{{CommandManualMenu}} This command is used to construct a CastFuse uniaxial material. The CastFuse material simulates the hysteretic response a cast yielding fuse (CSF) for conc...') |

No edit summary |

||

| (15 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{CommandManualMenu}} | {{CommandManualMenu}} | ||

This command is used to construct a CastFuse uniaxial material. The CastFuse material simulates the hysteretic response a cast yielding fuse (CSF) for concentrically braced frames. | This command is used to construct a CastFuse uniaxial material. The CastFuse material simulates the hysteretic response a cast yielding fuse (CSF) for concentrically braced frames. The details of a CSF-brace are discussed in Gray et al. [1,2]. Isotropic hardening is modeled with the rules developed by Filippou et al. [3]. | ||

{| | {| | ||

| Line 26: | Line 26: | ||

| '''$b''' || Strain hardening ratio | | '''$b''' || Strain hardening ratio | ||

|- | |- | ||

| '''$Ro''' || Parameter that controls the | | '''$Ro''' || Parameter that controls the Bauschinger effect. Recommended Values for $Ro=between 10 to 30 | ||

|- | |- | ||

| '''$cR1'' || Recommended Value $cR1=0.925 | | '''$cR1''' || Parameter that controls the Bauschinger effect. Recommended Value $cR1=0.925 | ||

|- | |- | ||

| '''$cR2'' || Recommended Value $cR2=0.150 | | '''$cR2''' || Parameter that controls the Bauschinger effect. Recommended Value $cR2=0.150 | ||

|- | |- | ||

| '''$a1''' || isotropic hardening parameter, increase of compression yield envelope as proportion of yield strength after a plastic | | '''$a1''' || isotropic hardening parameter, increase of compression yield envelope as proportion of yield strength after a plastic deformation of $a2*(P<sub>p</sub>/K<sub>p</sub>) | ||

|- | |- | ||

| '''$a2''' || isotropic hardening parameter (see explanation under $a1). (optional default = 1.0) | | '''$a2''' || isotropic hardening parameter (see explanation under $a1). (optional default = 1.0) | ||

|- | |- | ||

| '''$a3''' || isotropic hardening parameter, increase of tension yield envelope as proportion of yield strength after a plastic | | '''$a3''' || isotropic hardening parameter, increase of tension yield envelope as proportion of yield strength after a plastic deformation of $a4*(P<sub>p</sub>/K<sub>p</sub>) | ||

|- | |- | ||

| '''$a4''' || isotropic hardening parameter (see explanation under $a3). (optional default = 1.0) | | '''$a4''' || isotropic hardening parameter (see explanation under $a3). (optional default = 1.0) | ||

|} | |} | ||

---- | ---- | ||

{| | |||

| | |||

|- | |||

| Gray et al. [1] showed that the monotonic backbone curve of a CSF-brace with known properties (n, b<sub>o</sub>, h, L, fy, E) after yielding can be expressed as a close-form solution that is given by, | |||

|- | |||

| P = P<sub>p</sub>/cos(2d/L), in which d is the axial deformation of the brace at increment i and P<sub>p</sub> is the yield strength of the CSF-brace and is given by the following expression | |||

|- | |||

| P<sub>p</sub> = nb<sub>o</sub>h<sup>2</sup>f<sub>y</sub>/4L | |||

|- | |||

|The elastic stiffness of the CSF-brace is given by, | |||

|- | |||

|K<sub>p</sub> = nb<sub>o</sub>Eh<sup>3</sup>f<sub>y</sub>/6L<sup>3</sup> | |||

|- | |||

|- | |||

|} | |||

---- | |||

'''Examples:''' | '''Examples:''' | ||

{| | {| | ||

|- | |||

|- | |- | ||

| '''''1. Input parameters:''''' | | '''''1. Input parameters:''''' | ||

|- | |- | ||

|- | |- | ||

|- | |- | ||

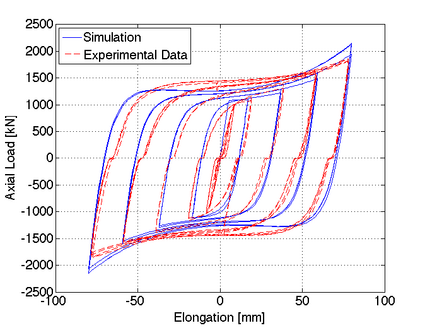

| Assume a CSF-Brace with n=10 yielding fingers, bo=250mm, h = 34mm fy=0.365kN/mm<sup>2</sup>, E=200kN/mm<sup>2</sup>, L=250mm. These design parameters are the ones used by Gray et al. [1] in order to design a CSF-brace that was tested at the University of Toronto. This brace is used for calibration of the simulated hysteretic response of the CastFuse material implemented in Opensees. For this purpose, the following set of parameters are utilized: | |||

|- | |||

|- | |||

| | |||

|- | |- | ||

| uniaxialMaterial Cast 1 10 250.0 34.0 0.365 200.0 250.0 0.000 19.0 0.925 0.15 0. | | uniaxialMaterial Cast 1 10 250.0 34.0 0.365 200.0 250.0 0.000 19.0 0.925 0.15 0.02 0.70 0.02 0.70 | ||

|- | |- | ||

| | |||

|- | |- | ||

| Using these properties a comparison between simulated and experimental response of a CSF brace tested at University of Toronto is shown in Figure 1. | | Using these properties a comparison between simulated and experimental response of a CSF brace tested at University of Toronto is shown in Figure 1. | ||

|- | |- | ||

| | | | ||

|- | |- | ||

| [[File: | | [[File:ExperimentalData-CastFuse.png|425px|thumb|left|Figure 1. CSF-Brace with n=10 yielding fingers, bo=250mm, h = 34mm fy=0.365kN/mm<sup>2</sup>, E=200kN/mm<sup>2</sup>, L=250mm, (Experimental data from Gray et al. [1])]] | ||

|- | |- | ||

|} | |} | ||

| Line 67: | Line 85: | ||

'''References''': | '''References''': | ||

{| | {| | ||

| style="width:5px" | '''[1]''' || Gray, M.G., Christopoulos, C., Packer, J.A., (2010) | | style="width:5px" | '''[1]''' || Gray, M.G., Christopoulos, C., Packer, J.A., (2010). "Cast Steel Yielding Fuse for Concentrically Braced Frames," Proceedings of the 9th U.S. National and 10th Canadian Conference on Earthquake Engineering, July 25-29, 2010, Toronto, Ontario, Canada, paper No. 595. | ||

|- | |||

| style="width:5px" | '''[2]''' || Gray, M.G., Christopoulos, C., Packer, J.A., Lignos, D.G. (2012). "Development, Validation and Modeling of the New Cast Steel Yielding Brace System,” Proceedings ASCE Structures Congress, March 29th-31st, Chicago, IL, USA, SEI institute. | |||

|- | |||

| style="width:5px" | '''[3]''' || Filippou, F. C., Popov, E. P., Bertero, V. V. (1983). "Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints," Report EERC 83-19, Earthquake Engineering Research Center, University of California, Berkeley. | |||

|- | |- | ||

|} | |} | ||

Code Developed by : <span style="color:blue"> by Dr. Dimitrios G. Lignos, (McGill University) </span> | Code Developed by : <span style="color:blue"> by Dr. Dimitrios G. Lignos, (McGill University) </span> | ||

Latest revision as of 19:43, 17 March 2012

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command is used to construct a CastFuse uniaxial material. The CastFuse material simulates the hysteretic response a cast yielding fuse (CSF) for concentrically braced frames. The details of a CSF-brace are discussed in Gray et al. [1,2]. Isotropic hardening is modeled with the rules developed by Filippou et al. [3].

| uniaxialMaterial Cast $matTag $n $bo $h $fy $E $L $b $Ro $cR1 $cR2 <$a1 $a2 $a3 $a4> |

| $matTag | integer tag identifying material |

| $n | Number of yield fingers of the CSF-brace |

| $bo | Width of an individual yielding finger at its base of the CSF-brace |

| $h | Thickness of an individual yielding finger |

| $fy | Yield strength of the steel material of the yielding finger |

| $E | Modulus of elasticity of the steel material of the yielding finger |

| $L | Height of an individual yielding finger |

| $b | Strain hardening ratio |

| $Ro | Parameter that controls the Bauschinger effect. Recommended Values for $Ro=between 10 to 30 |

| $cR1 | Parameter that controls the Bauschinger effect. Recommended Value $cR1=0.925 |

| $cR2 | Parameter that controls the Bauschinger effect. Recommended Value $cR2=0.150 |

| $a1 | isotropic hardening parameter, increase of compression yield envelope as proportion of yield strength after a plastic deformation of $a2*(Pp/Kp) |

| $a2 | isotropic hardening parameter (see explanation under $a1). (optional default = 1.0) |

| $a3 | isotropic hardening parameter, increase of tension yield envelope as proportion of yield strength after a plastic deformation of $a4*(Pp/Kp) |

| $a4 | isotropic hardening parameter (see explanation under $a3). (optional default = 1.0) |

| Gray et al. [1] showed that the monotonic backbone curve of a CSF-brace with known properties (n, bo, h, L, fy, E) after yielding can be expressed as a close-form solution that is given by, |

| P = Pp/cos(2d/L), in which d is the axial deformation of the brace at increment i and Pp is the yield strength of the CSF-brace and is given by the following expression |

| Pp = nboh2fy/4L |

| The elastic stiffness of the CSF-brace is given by, |

| Kp = nboEh3fy/6L3 |

Examples:

References:

| [1] | Gray, M.G., Christopoulos, C., Packer, J.A., (2010). "Cast Steel Yielding Fuse for Concentrically Braced Frames," Proceedings of the 9th U.S. National and 10th Canadian Conference on Earthquake Engineering, July 25-29, 2010, Toronto, Ontario, Canada, paper No. 595. |

| [2] | Gray, M.G., Christopoulos, C., Packer, J.A., Lignos, D.G. (2012). "Development, Validation and Modeling of the New Cast Steel Yielding Brace System,” Proceedings ASCE Structures Congress, March 29th-31st, Chicago, IL, USA, SEI institute. |

| [3] | Filippou, F. C., Popov, E. P., Bertero, V. V. (1983). "Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints," Report EERC 83-19, Earthquake Engineering Research Center, University of California, Berkeley. |

Code Developed by : by Dr. Dimitrios G. Lignos, (McGill University)