Pinching Limit State Material

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

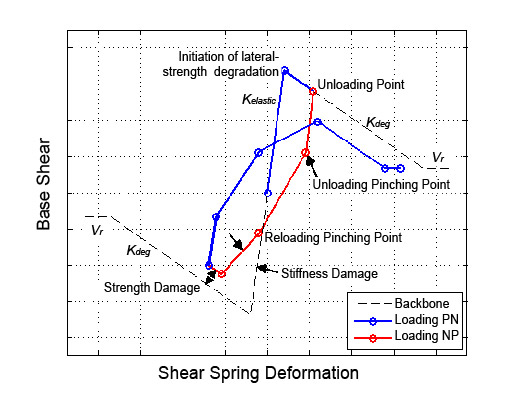

This command is used to construct a uniaxial material that simulates a pinched load-deformation response and exhibits degradation under cyclic loading. Cyclic degradation can be introduced using deformation and energy damage algorithms. Cyclic degradation can be imposed on reloading stiffness and backbone strength. The material in association with a RotationShearCurve material can monitor key deformation and forces in an associated frame element and utilize those values during analyses to adjust the force-deformation response. The material can be used in two modes: 1) direct input mode where all pinching and damage parameters are input; and 2) calibrated mode for shear-critical concrete columns where only key column properties are input for model to fully define pinching and damage parameters.

MODE 1: Direct Input

| uniaxialMaterial PinchingLimitStateMaterial $matTag

$nodeT $nodeB $driftAxis $Kelas $crvTyp $crvTag $YpinchUPN $YpinchRPN $XpinchRPN $YpinchUNP $YpinchRNP $XpinchRNP $dmgStrsLimE $dmgDispMax $dmgE1 $dmgE2 $dmgE3 $dmgE4 $dmgELim $dmgR1 $dmgR2 $dmgR3 $dmgR4 $dmgRLim $dmgRCyc $dmgS1 $dmgS2 $dmgS3 $dmgS4 $dmgSLim $dmgSCyc |

| $matTag | unique material object integer tag |

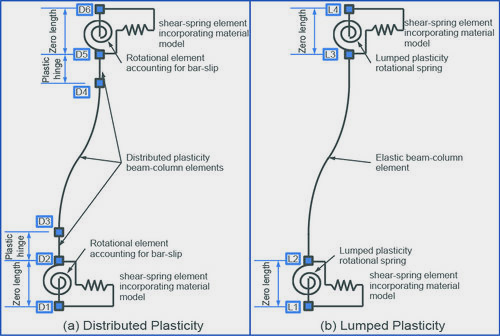

| $nodeT | integer node tag to define the first node at the extreme end of the associated flexural frame member (L3 or D5 in Figure) |

| $nodeB | integer node tag to define the last node at the extreme end of the associated flexural frame member (L2 or D2 in Figure) |

| $driftAxis | integer to indicate the drift axis in which lateral-strength degradation will occur. This axis should be orthogonal to the axis of measured rotation (see $rotAxis in Rotation Shear Curve definition)

driftAxis = 1 – Drift along the x-axis driftAxis = 2 – Drift along the y-axis driftAxis = 3 – Drift along the z-axis |

| $Kelas | floating point value to define the initial material elastic stiffness (Kelastic); Kelas > 0 |

| $crvTyp | integer flag to indicate the type of limit curve associated with this material.

crvTyp = 0 – No limit curve crvTyp = 1 – axial limit curve crvTyp = 2 – RotationShearCurve |

| $crvTag | integer tag for the unique limit curve object associated with this material |

| $YpinchUPN | floating point unloading force pinching factor for loading in the negative direction

Note: This value must be between zero and unity |

| $YpinchRPN | floating point reloading force pinching factor for loading in the negative direction

Note: This value must be between negative one and unity |

| $XpinchRPN | floating point reloading displacement pinching factor for loading in the negative direction

Note: This value must be between negative one and unity |

| $YpinchUNP | floating point unloading force pinching factor for loading in the positive direction

Note: This value must be between zero and unity |

| $YpinchRNP | floating point reloading force pinching factor for loading in the positive direction

Note: This value must be between negative one and unity |

| $XpinchRNP | floating point reloading displacement pinching factor for loading in the positive direction

Note: This value must be between negative one and unity |

| $dmgStrsLimE | floating point force limit for elastic stiffness damage (typically defined as the lowest of shear strength or shear at flexrual yielding). This value is used to compute the maximum deformation at flexural yield (δmax Eq. 1) and using the initial elastic stiffness (Kelastic) the monotonic energy (Emono Eq. 1) to yield. Input 1 if this type of damage is not required and set $dmgE1, $dmgE2, $dmgE3, $dmgE4, and $dmgELim to zero |

| $dmgDispMax | floating point for ultimate drift at failure (δmax Eq. 1) and is used for strength and stiffness damage. This value is used to compute the monotonic energy at axial failure (Emono Eq. 2) by computing the area under the backbone in the positive loading direction up to δmax. Input 1 if this type of damage is not required and set $dmgR1, $dmgR2, $dmgR3, $dmgR4, and $dmgRLim to zero for reloading stiffness damage. Similarly set $dmgS1, $dmgS2, $dmgS3, $dmgS4, and $dmgSLim to zero if reloading strength damage is not required |

| $dmgE1 $dmgE2 $dmgE3 $dmgE4 | floating point elastic damage factors α1,α2,α3,α4 shown in Eq. 1 |

| $dmgELim | floating point elastic damage limit Dlim shown in Eq. 1; Note: This value must be between zero and unity |

| $dmgR1 $dmgR2 $dmgR3 $dmgR4 | floating point reloading stiffness damage factors α1,α2,α3,α4 shown in Eq. 1 |

| $dmgRLim | floating point reloading stiffness damage limit Dlim shown in Eq. 1; Note: This value must be between zero and unity |

| $dmgRCyc | floating point cyclic reloading stiffness damage index; Note: This value must be between zero and unity |

| $dmgS1 $dmgS2 $dmgS3 $dmgS4 | floating point strength damage factors α1,α2,α3,α4 shown in Eq. 1 |

| $dmgSLim | floating point strength damage limit Dlim shown in Eq. 1; Note: This value must be between zero and unity |

| $dmgSCyc | floating point cyclic strength damage index; Note: This value must be between zero and unity |

NOTES:

Damage Model Equations:

Elastic stiffness, reloading stiffness, and strength can be adjusted using the following energy and displacement damage model (from Mitra and Lowes (2007)):

- <math>k_i = k_0(1 -\delta k_i)</math>

where <math>k_i</math> is the unloading stiffness at time <math>t_i</math>, <math>k_0</math> is the initial unloading stiffness (for the case of no damage), and <math>\delta k_i</math>(defined below) is the value of the stiffness damage index at time <math>t_i</math>.

- <math>d_{\text{max i}} = d_{\text{max 0}}(1 -\delta d_i)</math>

where <math>d_{\text{max i}}</math> is the deformation demand that defines the end of the reload cycle for increasing deformation demand, <math>d_{\text{max 0}} </math> is the maximum historic deformation demand (which would be the deformation demand defining the end of the reload cycle if degradation of reloading stiffness is ignored), and <math>\delta d_i</math> (defined below) is the value of reloading stiffness damage index at time <math>t_i</math>.

- <math>f_{\text{max i}} = f_{\text{max 0}}(1 -\delta f_i)</math>

where <math>f_{\text{max i}}</math> is the current envelope maximum strength at time <math>t_i</math>, <math>f_{\text{max 0}} </math> is the initial envelope maximum strength for the case of no damage, and <math>\delta f_i</math> (defined below) is the value of strength value index at time <math>t_i</math>.

The damage indices <math>\delta k_i</math>, <math>\delta d_i</math>, and <math>\delta f_i</math>, may be defined to be a function of displacement history only ($dmgType = "cycle") or displacement history and energy accumulation ($dmgType = "energy"). For either case, all of the damage indices are computed using the same basic equation.

If the damage indices are assumed to be a function of displacement history and energy accumulation, the unloading stiffness damage index, <math>\delta k_i</math> is computed as follows:

- <math>\delta k_i = \left( \text{gK1} (d_{max})^\text{gK3} + \text{gK2} \left (\frac{E_i}{E_\text{monotonic}} \right )^\text{gK3} \right ) <= \text{gKLim}</math>

where

- <math>(d_{max} = \text{max} \left[ \frac{d_\text{max i}}{\text{def}_\text{max}}, \frac{d_\text{min i}}{\text{def}_\text{min}} \right ]</math>

EXAMPLE:

PinchingLimitStateMaterial Example

DESCRIPTION:

REFERENCES:

1. LeBorgne M. R., 2012, "Modeling the Post Shear Failure Behavior of Reinforced Concrete Columns." Austin, Texas: University of Texas at Austin, PhD, 301.

2. LeBorgne M. R. , Ghannoum W. M., 2013, "Analytical Element for Simulating Lateral-Strength Degradation in Reinforced Concrete Columns and Other Frame Members," Journal of Structural Engineering, V. doi: 10.1061/(ASCE)ST.1943-541X.0000925

3. Ghannoum W. M., Moehle J. P., 2012, "Rotation-Based Shear Failure Model for Lightly Confined Reinforced Concrete Columns," Journal of Structural Engineering, V. 138, No. 10, 1267-78.

4. Mitra Nilanjan, Lowes Laura N., 2007, "Evaluation, Calibration, and Verification of a Reinforced Concrete Beam--Column Joint Model," Journal of Structural Engineering, V. 133, No. 1, 105-20.

Code Developed by: Matthew Leborgne and Wassim M. Ghannoum, University of Texas at Austin