BilinearOilDamper Material: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 51: | Line 51: | ||

|- | |- | ||

|- | |- | ||

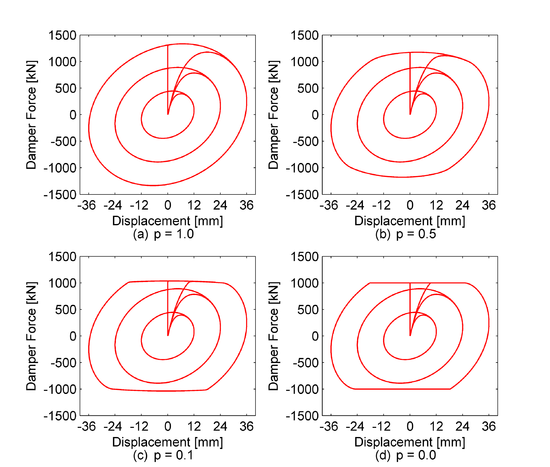

| [[File:BOD_1.png|550px|thumb|left| Oil Damper with various | | [[File:BOD_1.png|550px|thumb|left| Oil Damper with various post-relief viscous damping coefficient ratios]] | ||

|- | |- | ||

|- | |- | ||

| Line 65: | Line 65: | ||

|- | |- | ||

|- | |- | ||

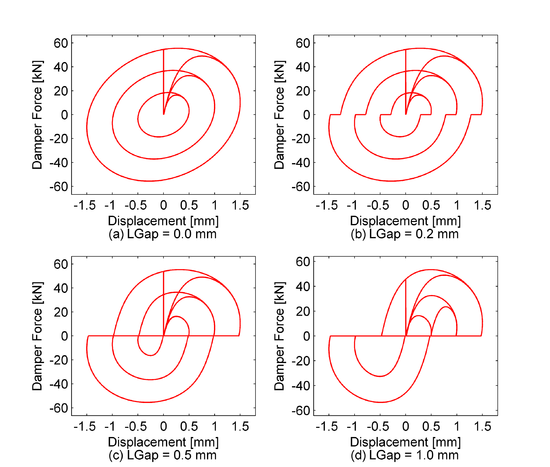

| [[File:BODgap_2.png|550px|thumb|left| Oil Damper with various | | [[File:BODgap_2.png|550px|thumb|left| Oil Damper with various gap lengths]] | ||

|- | |- | ||

|- | |- | ||

Revision as of 16:12, 15 June 2017

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command is used to construct a BilinearOilDamper material, which simulates the hysteretic response of bilinear oil dampers with relief valve. Two adaptive iterative algorithms have been implemented and validated to solve numerically the constitutive equations within a bilinear oil damper with a high-precision accuracy.

| uniaxialMaterial BilinearOilDamper $matTag $K $Cd <$Fr $p> <$LGap> < $NM $RelTol $AbsTol $MaxHalf> |

| $matTag | integer tag identifying material |

| $K | Elastic stiffness of linear spring to model the axial flexibility of an oil damper (brace and damper portion) |

| $Cd | Viscous damping coefficient of an oil damper (before relief) |

| $Fr | Damper relief load (default=1.0, Damper property) |

| $p | Post-relief viscous damping coefficient ratio (default=1.0, linear oil damper) |

| $LGap | gap length to simulate the gap length due to the pin tolerance (default=0.0: zero tolerance) |

| $NM | Employed adaptive numerical algorithm (default value NM = 1; 1 = Dormand-Prince54, 2=adaptive finite difference) |

| $RelTol | Tolerance for absolute relative error control of the adaptive iterative algorithm (default value 10^-6) |

| $AbsTol | Tolerance for absolute error control of adaptive iterative algorithm (default value 10^-10) |

| $MaxHalf | Maximum number of sub-step iterations within an integration step (default value 15) |

Examples:

References:

| [1] | Akcelyan, S. (2017). "Seismic retrofit of existing steel tall buildings with supplemental damping devices." Ph.D. Dissertation, McGill University, Canada. |

Code Developed and Implemented by : Sarven Akcelyan & Prof. Dimitrios G. Lignos, (McGill University)