Maxwell Material: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 40: | Line 40: | ||

|The sensitivity of the viscous damper with respect to its axial stiffness is shown in Figures 2 to 5 for the following set of parameters: | |The sensitivity of the viscous damper with respect to its axial stiffness is shown in Figures 2 to 5 for the following set of parameters: | ||

|- | |- | ||

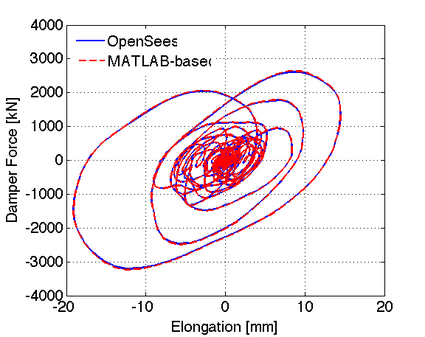

| [[File:Fig1.png| | | [[File:Fig1.png|425px|thumb|left|Figure 1. Viscous Damper with K=300.0 kN/mm, Cd=73.0kN(s/mm)<sup>0.6</sup>, a=0.60]] [[File:Fig2.png|425px|thumb|right|Figure 2. Viscous Damper with K=300.0 kN/mm, Cd=12.0kN(s/mm)<sup>1.0</sup>, a=1.0]] | ||

|- | |- | ||

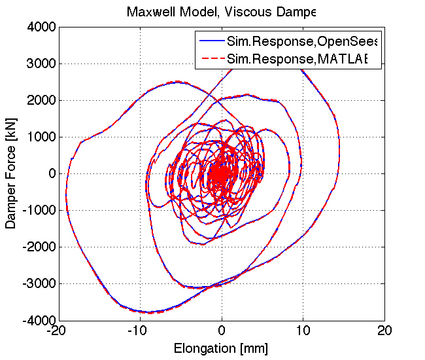

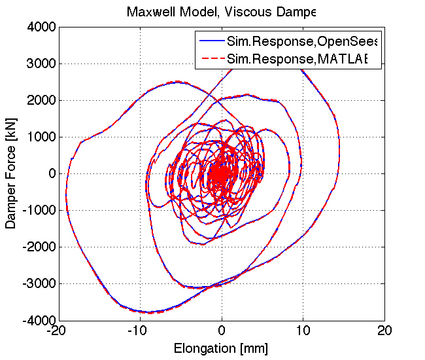

| [[File:Fig1.png|425px|thumb|left|Figure 2. Viscous Damper with K=300.0 kN/mm, Cd=683.0kN(s/mm)<sup>0.1</sup>, a=0.1]] | | [[File:Fig1.png|425px|thumb|left|Figure 2. Viscous Damper with K=300.0 kN/mm, Cd=683.0kN(s/mm)<sup>0.1</sup>, a=0.1]] [[File:Fig2.png|425px|thumb|right|Figure 2. Viscous Damper with K=300.0 kN/mm, Cd=1017.7kN(s/mm)<sup>0.01</sup>, a=0.01]] | ||

|- | |- | ||

|- | |- | ||

Revision as of 18:14, 21 August 2013

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command is used to construct a ViscousDamper material, which represents the Maxwell Model (linear spring and nonlinear dashpot in series). The Maxwell material simulates the hysteretic response of viscous dampers.

| uniaxialMaterial ViscousDamper $matTag $K $Cd $alpha |

| $matTag | integer tag identifying material |

| $K | Elastic stiffness of linear spring (to model the axial flexibility of a viscous damper (brace and damper portion) |

| $Cd | Viscous parameter of damper |

| $alpha | Viscous damper exponent |

Examples:

| 1. Input parameters: |

| Assume a viscous damper with axial stiffness K=300.0kN/mm, viscous parameter Cd=280.3kN(s/mm)0.3, and exponent a=0.30. |

| The input parameters for the material should be as follows: |

| uniaxialMaterial ViscousDamper 1 300 280.3 0.30 |

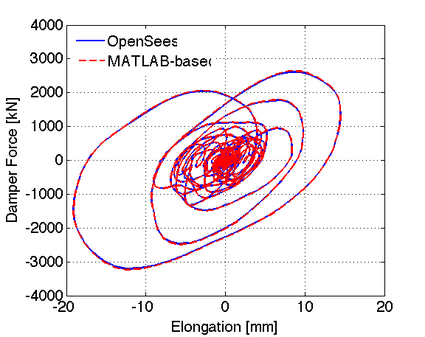

| Using these properties, Figure 1 shows the hysteretic response of this damper for sinusoidal displacement increments of 12, 24 and 36mm and a frequency f = 0.5Hz. |

| The sensitivity of the viscous damper with respect to its axial stiffness is shown in Figures 2 to 5 for the following set of parameters: |

|

|

| 2. Tcl input file for Viscous Damper Calibration. |

| 3. OpenSees Example of 1-story steel moment frame with a viscous damper: (to be posted) |

References:

| [1] | Olsson, A.K., and Austrell, P-E., (2001), "A fitting procedure for viscoelastic-elastoplastic material models," Proceedings of the Second European Conference on Constitutive Models for Rubber, Germany, 2001. |

| [2] | Ottosen, N.S., and Ristinmaa, M., (1999). "The mechanics of constitutive modelling, (Numerical and thermodynamical topics)," Lund University,Division of Solid Mechanics, Sweden, 1999. |

Code Developed by : Prof. Kazuhiko Kasai (Tokyo Institute of Technology) and implemented by Sarven Akcelyan & Prof. Dimitrios G. Lignos, (McGill University)