KikuchiAikenHDR Material: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 32: | Line 32: | ||

|- | |- | ||

| '''X0.6-0MPa''' || Bridgestone X0.6, zero compressive stress, up to 400% shear strain | | '''X0.6-0MPa''' || Bridgestone X0.6, zero compressive stress, up to 400% shear strain | ||

|- | |||

| '''X0.4''' || Bridgestone X0.4, standard compressive stress, up to 400% shear strain | |||

|- | |||

| '''X0.4-0MPa''' || Bridgestone X0.4, zero compressive stress, up to 400% shear strain | |||

|- | |||

| '''X0.3''' || Bridgestone X0.3, standard compressive stress, up to 400% shear strain | |||

|- | |||

| '''X0.3-0MPa''' || Bridgestone X0.3, zero compressive stress, up to 400% shear strain | |||

|} | |} | ||

Latest revision as of 03:15, 1 February 2017

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

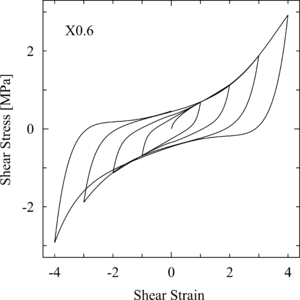

This command is used to construct a uniaxial KikuchiAikenHDR material object. This material model produces nonlinear hysteretic curves of high damping rubber bearings (HDRs).

| uniaxialMaterial KikuchiAikenHDR $matTag $tp $ar $hr <-coGHU $cg $ch $cu> <-coMSS $rs $rf> |

| $matTag | integer tag identifying material |

| $tp | rubber type (see note 1) |

| $ar | area of rubber [unit: m^2] (see note 2) |

| $hr | total thickness of rubber [unit: m] (see note 2) |

| $cg $ch $cu | correction coefficients for equivalent shear modulus ($cg), equivalent viscous daming ratio ($ch), ratio of shear force at zero displacement ($cu). |

| $rs $rf | reduction rate for stiffness ($rs) and force ($rf) (see note 3) |

NOTES:

1) Following rubber types for $tp are available:

| X0.6 | Bridgestone X0.6, standard compressive stress, up to 400% shear strain |

| X0.6-0MPa | Bridgestone X0.6, zero compressive stress, up to 400% shear strain |

| X0.4 | Bridgestone X0.4, standard compressive stress, up to 400% shear strain |

| X0.4-0MPa | Bridgestone X0.4, zero compressive stress, up to 400% shear strain |

| X0.3 | Bridgestone X0.3, standard compressive stress, up to 400% shear strain |

| X0.3-0MPa | Bridgestone X0.3, zero compressive stress, up to 400% shear strain |

2) This material uses SI unit in calculation formula. $ar and $hr must be converted into [m^2] and [m], respectively.

3) $rs and $rf are available if this material is applied to multipleShearSpring (MSS) element. Recommended values are $rs=1/sum(i=0,n-1){ sin(pi*i/n)^2} and $rf=1/sum(i=0,n-1){sin(pi*i/n)}, where n is the number of springs in the MSS. For example, when n=8, $rs=0.2500, $rf=0.1989.

EXAMPLE:

Code Developed by: mkiku