RotationShearCurve: Difference between revisions

(Created page with '{{CommandManualMenu}} This command is used to construct a limit surface that defines the ultimate rotation of a plastic hinge that triggers lateral-strength degradation in Pinc...') |

Wuhaoshrek (talk | contribs) |

||

| (18 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

This command is used to construct a limit surface that defines the ultimate | This command is used to construct a limit surface that defines the ultimate deformation between two nodes and/or the ultimate force that trigger lateral-strength degradation in the [[Pinching Limit State Material]]. | ||

The curve can be used in two modes: 1) direct input mode where all parameters are input; and 2) calibrated mode | The curve can be used in two modes: 1) direct input mode, where all parameters are input; and 2) calibrated mode for shear-critical concrete columns, where only key column properties are input for model to fully define pinching and damage parameters. | ||

Note: when both strength and rotation limits are used. Lateral-strength degradation is triggered in the material model when the first limit is reached. | Note: when both strength and rotation limits are used. Lateral-strength degradation is triggered in the material model when the first limit is reached. | ||

| Line 14: | Line 11: | ||

{| | {| | ||

| style="background:yellow; color:black; width:800px" | ''' | | style="background:yellow; color:black; width:800px" | '''limitCurve RotationShearCurve $crvTag $eleTag $ndI $ndJ $rotAxis $Vn $Vr $Kdeg $rotLim''' | ||

|} | |} | ||

| Line 28: | Line 17: | ||

{| | {| | ||

| style="width:150px" | '''$ | | style="width:150px" | '''$crvTag ''' || unique limit curve object integer tag | ||

|- | |- | ||

| '''$ | | '''$eleTag''' || integer element tag to define the associated beam-column element used to extract axial load | ||

|- | |- | ||

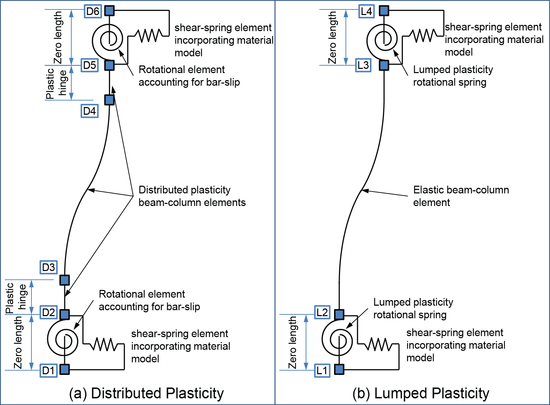

| '''$ | | '''$ndI''' || integer node tag to define the node at the extreme end of the frame member bounding the plastic hinge (L1 or D1 for bottom spring and L4 or D6 for top spring in Figure) | ||

|- | |- | ||

| '''$ | | '''$ndJ''' ||integer node tag to define the node bounding the plastic hinge (L2 or D3 for bottom spring and L3 or D4 for top spring in Figure) | ||

|- | |- | ||

| '''$ | | '''$rotAxis''' || integer to indicate axis of measured rotation when triggering lateral-strength degradation | ||

|- | |- | ||

| | | || rotAxis = 3 – Rotation about z-axis – 2D | ||

rotAxis = 4 – Rotation about x-axis – 3D | |||

rotAxis = 5 – Rotation about y-axis – 3D | |||

rotAxis = 6 – Rotation about z-axis – 3D | |||

|- | |- | ||

| '''$ | | '''$Vn''' || floating point value to define the ultimate strength in material model | ||

|- | |- | ||

| | | || Vn = -1 – strength limit is not used. | ||

Vn > 0 – strength limit is the input value | |||

|- | |- | ||

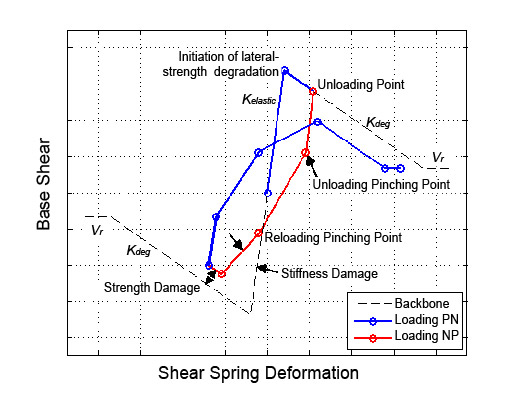

| '''$ | | '''$Vr''' || floating point value to define the backbone residual strength | ||

|- | |- | ||

| | | || Vr = -1 – Residual strength = 0.2*(max. force in material model at initiation of degradation) | ||

-1 < Vr < 0 – Residual shear strength = Vr*(max. force in material model at initiation of degradation) | |||

Vr > 0 – Residual strength is the input value | |||

|- | |- | ||

| '''$ | | '''$Kdeg''' || floating point value to define the backbone degrading slope of the material model. | ||

|- | |- | ||

| | | || Note: the degrading slope must be less than zero. | ||

|- | |- | ||

| '''$ | | '''$rotLim''' || floating point value to limit the rotational capacity across the plastic hinge (difference between $ndI and $ndJ in absolute value). When this value (radians) is exceeded during the analysis degrading behavior is triggered in the material model. | ||

|- | |- | ||

|} | |} | ||

== '''MODE 2: Calibrated Model for Shear-Critical Concrete Columns''' == | == '''MODE 2: Calibrated Model for Shear-Critical Concrete Columns''' == | ||

| Line 93: | Line 59: | ||

{| | {| | ||

| style="background:yellow; color:black; width:800px" | ''' | | style="background:yellow; color:black; width:800px" | '''limitCurve RotationShearCurve $crvTag $eleTag $ndI $ndJ $rotAxis $Vn $Vr $Kdeg $defType $b $d $h $L $st $As $Acc $ld $db $rhot $f'c $fy $fyt $delta''' | ||

|} | |} | ||

| Line 99: | Line 65: | ||

{| | {| | ||

| style="width:150px" | '''$ | | style="width:150px" | '''$crvTag''' || unique limit curve object integer tag | ||

|- | |- | ||

| '''$ | | '''$eleTag''' || integer element tag to define the associated beam-column element used to extract axial load | ||

|- | |- | ||

| '''$ | | '''$ndI''' || integer node tag to define the node at one end of the region for which limiting rotations are defined (see $defType) | ||

|- | |- | ||

| '''$ | | '''$ndJ''' || integer node tag to define the node at the other end of the region for which limiting rotations are defined (see $defType) | ||

|- | |- | ||

| '''$ | | '''$rotAxis''' || integer to indicate axis of measured rotation when triggering lateral-strength degradation. | ||

|- | |||

| || rotAxis = 3 – Rotation about z-axis – 2D | |||

rotAxis = 4 – Rotation about x-axis – 3D | |||

rotAxis = 5 – Rotation about y-axis – 3D | |||

rotAxis = 6 – Rotation about z-axis – 3D | |||

|- | |||

| '''$Vn''' || floating point value to define the nominal shear strength | |||

|- | |||

| || Vn = -1 – Shear strength limit is not used | |||

Vn = 0 – Shear strength limit is calculated using ASCE 41-06 Eq. 6-4 | |||

Vn > 0 – Shear strength limit is the input value | |||

Note: Shear capacity calculated according to ASCE 41 only gives the capacity with the k factor equal to 1 (i.e., shear capacity at small deformations) | |||

|- | |||

| '''$Vr''' || floating point value to define the backbone residual shear strength | |||

|- | |||

| || Vr = -1 – Residual shear strength = 0.2*( max. force in material model at initiation of degradation) | |||

-1 < Vr < 0 – Residual shear strength = Vr*( max. force in material model at initiation of degradation) | |||

Vr > 0 – Residual shear strength is the input value | |||

|- | |||

| '''$Kdeg''' || floating point value to define the backbone degrading slope. | |||

|- | |||

| || Kdeg = 0 – Degrading slope calculated by calibrated regression model. | |||

Kdeg < 0 – Degrading slope is the input value | |||

|- | |- | ||

| '''$ | | '''$defType''' || integer flag to define which rotation-based shear failure model is used | ||

|- | |- | ||

| | | || | ||

1 – Flexure-Shear capacity based on θ_f rotation capacity (Eq. 4.4; Leborgne 2012) | |||

For this case select $ndI=D1 or L1 and $ndJ=D3 or L2 for the bottom spring in Fig. 1 | |||

2 – Flexure-Shear capacity based on θ_total rotation capacity (Ghannoum and Moehle 2012) | |||

For this case select $ndI=D1 or L1 and $ndJ=D3 or L2 for the bottom spring in Fig. 1 | |||

3 – Flexure-Shear capacity based on θflexural rotation capacity (Ghannoum and Moehle 2012) | |||

For this case select $ndI=D2 and $ndJ=D3 for the bottom spring in Fig. 1 | |||

4 – Flexure-Shear capacity based on θ_total-plastic rotation capacity (Ghannoum and Moehle 2012) | |||

For this case select $ndI=L1 and $ndJ=L2 for the bottom spring in Fig. 1 | |||

5 – Flexure-Shear capacity based on θ_flexural-plastic rotation capacity (Ghannoum and Moehle 2012) | |||

This is a special case not shown in Fig. 1 where column flexural plastic deformations are simulated separately from bar-slip induced plastic rotations in a lumped-plasticity model | |||

|- | |- | ||

| '''$b''' || floating point column width (inches) | | '''$b''' || floating point column width (inches) | ||

| Line 134: | Line 131: | ||

| '''$h''' || floating point column height (inches) | | '''$h''' || floating point column height (inches) | ||

|- | |- | ||

| '''$ | | '''$L''' || floating point column clear span length (inches) | ||

|- | |- | ||

| '''$st''' || floating point transverse reinforcement spacing (inches) along column height | | '''$st''' || floating point transverse reinforcement spacing (inches) along column height | ||

| Line 153: | Line 150: | ||

|- | |- | ||

| '''$fyt''' || floating point transverse steel yield strength (ksi) | | '''$fyt''' || floating point transverse steel yield strength (ksi) | ||

|- | |||

| '''$delta''' || floating point offset (radians) added to shear failure models to adjust shear failure location. | |||

|- | |||

| || Note: This value should remain at zero to use the model as per calibration | |||

|} | |} | ||

| Line 162: | Line 163: | ||

[[Image:PinchingLimitStateMaterial1-2.jpg]] | [[Image:PinchingLimitStateMaterial1-2.jpg]] | ||

| Line 196: | Line 182: | ||

3. Ghannoum W. M., Moehle J. P., 2012, "Rotation-Based Shear Failure Model for Lightly Confined Reinforced Concrete Columns," Journal of Structural Engineering, V. 138, No. 10, 1267-78. | 3. Ghannoum W. M., Moehle J. P., 2012, "Rotation-Based Shear Failure Model for Lightly Confined Reinforced Concrete Columns," Journal of Structural Engineering, V. 138, No. 10, 1267-78. | ||

---- | |||

Code Developed by: <span style="color:blue"> Matthew Leborgne and Wassim M. Ghannoum, University of Texas at Austin</span> | |||

Latest revision as of 20:59, 23 April 2014

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command is used to construct a limit surface that defines the ultimate deformation between two nodes and/or the ultimate force that trigger lateral-strength degradation in the Pinching Limit State Material.

The curve can be used in two modes: 1) direct input mode, where all parameters are input; and 2) calibrated mode for shear-critical concrete columns, where only key column properties are input for model to fully define pinching and damage parameters.

Note: when both strength and rotation limits are used. Lateral-strength degradation is triggered in the material model when the first limit is reached.

MODE 1: Direct Input

| limitCurve RotationShearCurve $crvTag $eleTag $ndI $ndJ $rotAxis $Vn $Vr $Kdeg $rotLim |

| $crvTag | unique limit curve object integer tag |

| $eleTag | integer element tag to define the associated beam-column element used to extract axial load |

| $ndI | integer node tag to define the node at the extreme end of the frame member bounding the plastic hinge (L1 or D1 for bottom spring and L4 or D6 for top spring in Figure) |

| $ndJ | integer node tag to define the node bounding the plastic hinge (L2 or D3 for bottom spring and L3 or D4 for top spring in Figure) |

| $rotAxis | integer to indicate axis of measured rotation when triggering lateral-strength degradation |

| rotAxis = 3 – Rotation about z-axis – 2D

rotAxis = 4 – Rotation about x-axis – 3D rotAxis = 5 – Rotation about y-axis – 3D rotAxis = 6 – Rotation about z-axis – 3D | |

| $Vn | floating point value to define the ultimate strength in material model |

| Vn = -1 – strength limit is not used.

Vn > 0 – strength limit is the input value | |

| $Vr | floating point value to define the backbone residual strength |

| Vr = -1 – Residual strength = 0.2*(max. force in material model at initiation of degradation)

-1 < Vr < 0 – Residual shear strength = Vr*(max. force in material model at initiation of degradation) Vr > 0 – Residual strength is the input value | |

| $Kdeg | floating point value to define the backbone degrading slope of the material model. |

| Note: the degrading slope must be less than zero. | |

| $rotLim | floating point value to limit the rotational capacity across the plastic hinge (difference between $ndI and $ndJ in absolute value). When this value (radians) is exceeded during the analysis degrading behavior is triggered in the material model. |

MODE 2: Calibrated Model for Shear-Critical Concrete Columns

| limitCurve RotationShearCurve $crvTag $eleTag $ndI $ndJ $rotAxis $Vn $Vr $Kdeg $defType $b $d $h $L $st $As $Acc $ld $db $rhot $f'c $fy $fyt $delta |

| $crvTag | unique limit curve object integer tag |

| $eleTag | integer element tag to define the associated beam-column element used to extract axial load |

| $ndI | integer node tag to define the node at one end of the region for which limiting rotations are defined (see $defType) |

| $ndJ | integer node tag to define the node at the other end of the region for which limiting rotations are defined (see $defType) |

| $rotAxis | integer to indicate axis of measured rotation when triggering lateral-strength degradation. |

| rotAxis = 3 – Rotation about z-axis – 2D

rotAxis = 4 – Rotation about x-axis – 3D rotAxis = 5 – Rotation about y-axis – 3D rotAxis = 6 – Rotation about z-axis – 3D | |

| $Vn | floating point value to define the nominal shear strength |

| Vn = -1 – Shear strength limit is not used

Vn = 0 – Shear strength limit is calculated using ASCE 41-06 Eq. 6-4 Vn > 0 – Shear strength limit is the input value Note: Shear capacity calculated according to ASCE 41 only gives the capacity with the k factor equal to 1 (i.e., shear capacity at small deformations) | |

| $Vr | floating point value to define the backbone residual shear strength |

| Vr = -1 – Residual shear strength = 0.2*( max. force in material model at initiation of degradation)

-1 < Vr < 0 – Residual shear strength = Vr*( max. force in material model at initiation of degradation) Vr > 0 – Residual shear strength is the input value | |

| $Kdeg | floating point value to define the backbone degrading slope. |

| Kdeg = 0 – Degrading slope calculated by calibrated regression model.

Kdeg < 0 – Degrading slope is the input value | |

| $defType | integer flag to define which rotation-based shear failure model is used |

|

1 – Flexure-Shear capacity based on θ_f rotation capacity (Eq. 4.4; Leborgne 2012) For this case select $ndI=D1 or L1 and $ndJ=D3 or L2 for the bottom spring in Fig. 1 2 – Flexure-Shear capacity based on θ_total rotation capacity (Ghannoum and Moehle 2012) For this case select $ndI=D1 or L1 and $ndJ=D3 or L2 for the bottom spring in Fig. 1 3 – Flexure-Shear capacity based on θflexural rotation capacity (Ghannoum and Moehle 2012) For this case select $ndI=D2 and $ndJ=D3 for the bottom spring in Fig. 1 4 – Flexure-Shear capacity based on θ_total-plastic rotation capacity (Ghannoum and Moehle 2012) For this case select $ndI=L1 and $ndJ=L2 for the bottom spring in Fig. 1 5 – Flexure-Shear capacity based on θ_flexural-plastic rotation capacity (Ghannoum and Moehle 2012) This is a special case not shown in Fig. 1 where column flexural plastic deformations are simulated separately from bar-slip induced plastic rotations in a lumped-plasticity model | |

| $b | floating point column width (inches) |

| $d | floating point column depth (inches) |

| $h | floating point column height (inches) |

| $L | floating point column clear span length (inches) |

| $st | floating point transverse reinforcement spacing (inches) along column height |

| $As | floating point total area (inches squared) of longitudinal steel bars in section |

| $Acc | floating point gross confined concrete area (inches squared) bounded by the transverse reinforcement in column section |

| $ld | floating point development length (inches) of longitudinal bars using ACI 318-11 Eq. 12-1 and Eq. 12-2 |

| $db | floating point diameter (inches) of longitudinal bars in column section |

| $rhot | floating point transverse reinforcement ratio (Ast/st.db) |

| $f'c | floating point concrete compressive strength (ksi) |

| $fy | floating point longitudinal steel yield strength (ksi) |

| $fyt | floating point transverse steel yield strength (ksi) |

| $delta | floating point offset (radians) added to shear failure models to adjust shear failure location. |

| Note: This value should remain at zero to use the model as per calibration |

DESCRIPTION:

EXAMPLE:

PinchingLimitStateMaterial Example

REFERENCES:

1. LeBorgne M. R., 2012, "Modeling the Post Shear Failure Behavior of Reinforced Concrete Columns." Austin, Texas: University of Texas at Austin, PhD, 301.

2. LeBorgne M. R. , Ghannoum W. M., 2013, "Analytical Element for Simulating Lateral-Strength Degradation in Reinforced Concrete Columns and Other Frame Members," Journal of Structural Engineering, V. doi: 10.1061/(ASCE)ST.1943-541X.0000925

3. Ghannoum W. M., Moehle J. P., 2012, "Rotation-Based Shear Failure Model for Lightly Confined Reinforced Concrete Columns," Journal of Structural Engineering, V. 138, No. 10, 1267-78.

Code Developed by: Matthew Leborgne and Wassim M. Ghannoum, University of Texas at Austin