User talk:Kkolozvari: Difference between revisions

Kkolozvari (talk | contribs) |

Kkolozvari (talk | contribs) |

||

| Line 174: | Line 174: | ||

* SFI_MVLEM_SP4.tcl – model generation and definition of analysis parameters | * SFI_MVLEM_SP4.tcl – model generation and definition of analysis parameters | ||

* gravity.tcl – application of gravity load | * gravity.tcl – application of gravity load | ||

* dispControl.tcl – application of lateral | * dispControl.tcl – application of lateral displacement history (run this file) | ||

* LibAnalysisStaticParameters.tcl - definition of static analysis parameters | * LibAnalysisStaticParameters.tcl - definition of static analysis parameters | ||

* LibGeneratePeaks.tcl - generation of displacement history | * LibGeneratePeaks.tcl - generation of displacement history | ||

Revision as of 17:32, 11 July 2015

Element MVLEM

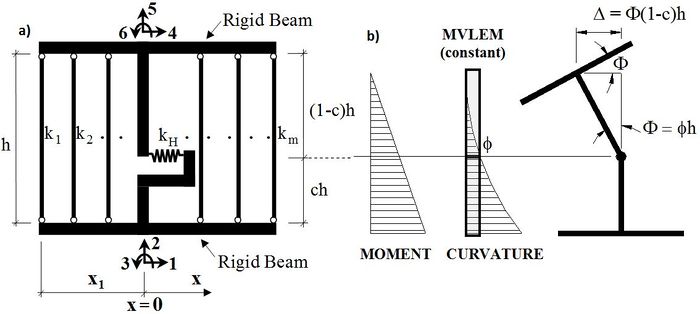

The MVLEM element command is used to generate a two-dimensional Multiple-Vertical-Line-Element-Model (MVLEM; Vulcano et al., 1988; Orakcal et al., 2004) for simulation of flexure-dominated RC wall behavior. A single model element incorporates six global degrees of freedom, three of each located at the center of rigid top and bottom beams, as illustrated in Figure 1a. The axial/flexural response of the MVLEM is simulated by a series of uniaxial elements (or macro-fibers) connected to the rigid beams at the top and bottom (e.g., floor) levels, whereas the shear response is described by a shear spring located at height ch from the bottom of the wall element. Shear and flexural responses of the model element are uncoupled. The relative rotation between top and bottom faces of the wall element occurs about the point located on the central axis of the element at height ch (Figure 1b). Rotations and resulting transverse displacements are calculated based on the wall curvature, derived from section and material properties, corresponding to the bending moment at height ch of each element (Figure 1b). A value of c=0.4 was recommended by Vulcano et al. (1988) based on comparison of the model response with experimental results.

Source: /usr/local/cvs/OpenSees/SRC/element/MVLEM/

Input Format:

| Element MVLEM $eleTag $Dens $iNode $jNode $m $c -thick {Thicknesses} -width {Widths} -rho {Reinforcing_ratios} -matConcrete {Concrete_tags} -matSteel {Steel_tags} -matShear {Shear_tag} |

| $eleTag | Unique element object tag |

| $Dens | Wall density |

| $iNode $jNode | End node tags |

| $m | Number of element macro-fibers |

| $c | Location of center of rotation with from the iNode, c = 0.4 (recommended) |

| {Thicknesses} | Array of m macro-fiber thicknesses |

| {Widths} | Array of m macro-fiber widths |

| {Reinforcing_ratios} | Array of m reinforcing ratios corresponding to macro-fibers; for each fiber: rho,i = As,i/Agross,i (1 < i < m) |

| {Concrete _tags} | Array of m uniaxialMaterial tags for concrete |

| {Steel_tags} | Array of m uniaxialMaterial tags for steel |

| {Shear_tag} | Tag of uniaxialMaterial for shear material |

Element Recorders:

The following recorders are available with the MVLEM element:

| globalForce | Element global forces |

| Curvature | Element curvature |

| Shear_Force_Deformation | Element shear force-deformation relationship |

| Fiber_Strain | Vertical strain in m fibers along the cross-section |

| Fiber_Stress_Concrete | Vertical concrete stress in m fibers along the cross-section |

| Fiber_Stress_Steel | Vertical steel stress in m fibers along the cross-section |

Examples:

Element MVLEM 1 0.0 1 2 8 0.4 -thick 4 4 4 4 4 4 4 4 -width 7.5 1.5 7.5 7.5 7.5 7.5 1.5 7.5 -rho 0.0293 0.0 0.0033 0.0033

0.0033 0.0033 0.0 0.0293 -matConcrete 3 4 4 4 4 4 4 3 -matSteel 1 2 2 2 2 2 2 1 -matShear 5

Recorder Element -file MVLEM_Fgl.out -time -ele 1 globalForce

Recorder Element -file MVLEM_FiberStrain.out -time -ele 1 Fiber_Strain

References:

Developed and Implemented by:

Kristijan Kolozvari, California State University Fullerton

Kutay Orakcal, Bogazici University, Istanbul, Turkey

John Wallace, Univeristy of California, Los Angeles

1) Orakcal K., Conte J.P., and Wallace J.W. (2004). “Flexural Modeling of Reinforced Concrete Structural Walls - Model Attributes”, ACI Structural Journal, V. 101, No. 5, pp 688-698.

2) Vulcano A., Bertero V.V., and Colotti V. (1988). “Analytical Modeling of RC Structural Walls”, Proceedings, 9th World Conference on Earthquake Engineering, V. 6, Tokyo-Kyoto, Japan, pp. 41-46.

Element SFI_MVLEM

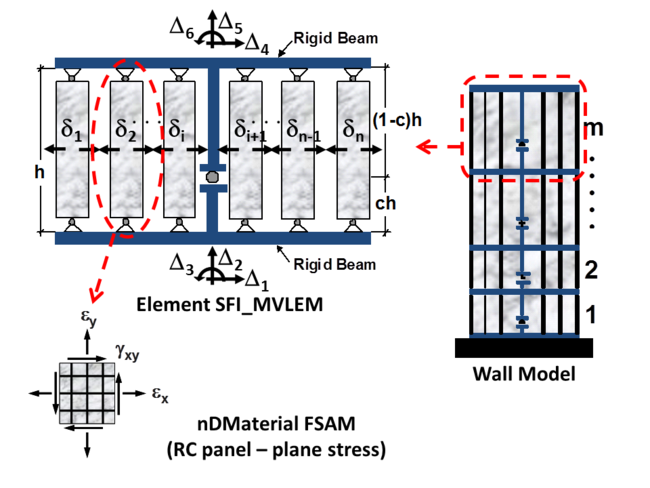

The SFI_MVLEM command is used to construct a Shear-Flexure Interaction Multiple-Vertical-Line-Element Model (SFI-MVLEM, Kolozvari et al., 2014a, b), which captures interaction between axial/flexural and shear behavior of RC structural walls and columns under cyclic loading. The SFI_MVLEM element (Figure 1) incorporates 2-D RC panel behavior described by the Fixed-Strut-Angle-Model (nDMaterial FSAM; Ulugtekin, 2010; Orakcal et al., 2012), into a 2-D macroscopic fiber-based model (MVLEM). The interaction between axial and shear behavior is captured at each RC panel (macro-fiber) level, which further incorporates interaction between shear and flexural behavior at the SFI_MVLEM element level.

Source: /usr/local/cvs/OpenSees/SRC/element/SFI_MVLEM/

Input Format:

| Element SFI_MVLEM $eleTag $iNode $jNode $m $c -thick {Thicknesses} -width {Widths} -mat {Material_tags} |

| $eleTag | Unique element object tag |

| $iNode $jNode | End node tags |

| $m | Number of element macro-fibers |

| $c | Location of center of rotation with from the iNode, c = 0.4 (recommended) |

| {Thicknesses} | Array of m macro-fiber thicknesses |

| {Widths} | Array of m macro-fiber widths |

| {Material_tags} | Array of m macro-fiber nDMaterial1 tags |

1SFI_MVLEM element shall be used with nDMaterial FSAM, which is a 2-D plane-stress constitutive relationship representing reinforced concrete panel behavior.

Element Recorders:

The following recorders are available with the SFI_MVLEM element:

| globalForce | Element global forces |

| Curvature | Element curvature |

| ShearDef | Element shear deformation |

| RCPanel $fibTag $Response | Returns RC panel (macro-fiber) $Response for a $fibTag-th panel (1 ≤ fibTag ≤ m). For available $Response-s refer to nDMaterial FSAM (LINK). |

Examples:

Element SFI_MVLEM 1 1 2 5 0.4 -thick 6 6 6 6 6 -width 9 10 10 10 9 -mat 7 6 6 6 7

Recorder Element -file SFI_MVLEM_Fgl.out -time -ele 1 2 3 globalForce

Recorder Element -file SFI_MVLEM_panel_strain.out -time -ele 1 RCPanel 1 panel_strain

References:

Developed and Implemented by:

Kristijan Kolozvari, California State University Fullerton

Kutay Orakcal, Bogazici University, Istanbul, Turkey

John Wallace, Univeristy of California, Los Angeles

1) Kolozvari K., Orakcal K., and Wallace J. W. (2015). ”Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls. I: Theory”, ASCE Journal of Structural Engineering, 141(5), 04014135 doi

2) Kolozvari K., Tran T., Orakcal K., and Wallace, J.W. (2015). ”Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls. II: Experimental Validation”, ASCE Journal of Structural Engineering, 141(5), 04014136 doi

3) Kolozvari K. (2013). “Analytical Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls”, PhD Dissertation, University of California, Los Angeles.

Example 1. Simulation of Shear-Flexural Behavior of a Medium-Rise RC Wall Specimen under Cyclic Loading using the SFI-MVLEM Model

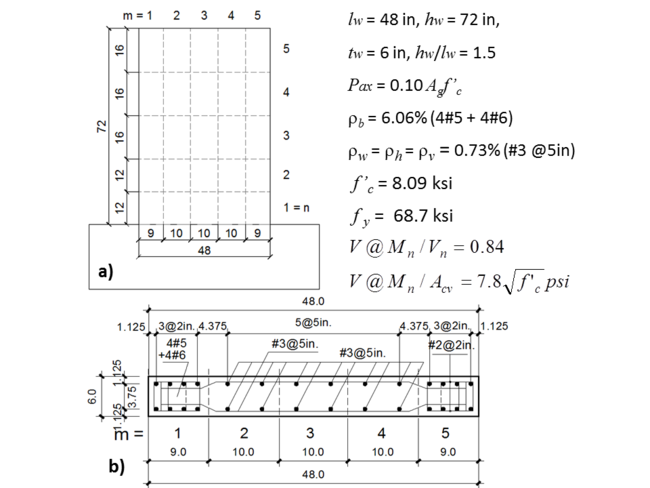

The behavior of RC wall specimen RW-A15-P10-S78 (Tran and Wallace, 2012) tested under constant axial load and cyclic lateral displacement history applied at the top of the wall is predicted using the SFI_MVLEM model. The input parameters and output results are presented in the following sections.

E.1. Model Calibration

Basic properties of the specimen with model discretization are shown on Figure E1.1. Detailed information about the test specimen can be found in paper by Tran and Wallace (2012), whereas details of model calibration are provided by Kolozvari (2013) and Kolozvari et al. (2015b).

E.2. Input Files

Input files (.tcl) used to build the wall model and perform displacement-controlled analysis can be found in MassoneWall_TrussExample2.zip):

- SFI_MVLEM_SP4.tcl – model generation and definition of analysis parameters

- gravity.tcl – application of gravity load

- dispControl.tcl – application of lateral displacement history (run this file)

- LibAnalysisStaticParameters.tcl - definition of static analysis parameters

- LibGeneratePeaks.tcl - generation of displacement history

E.3. Analysis Results

The following sub-section presents analytical results obtained for the test specimen described above, using the input files provided in Appendix A. The results include global wall responses (compared against experimental results), model element responses, and individual RC panel (macro-fiber) responses.

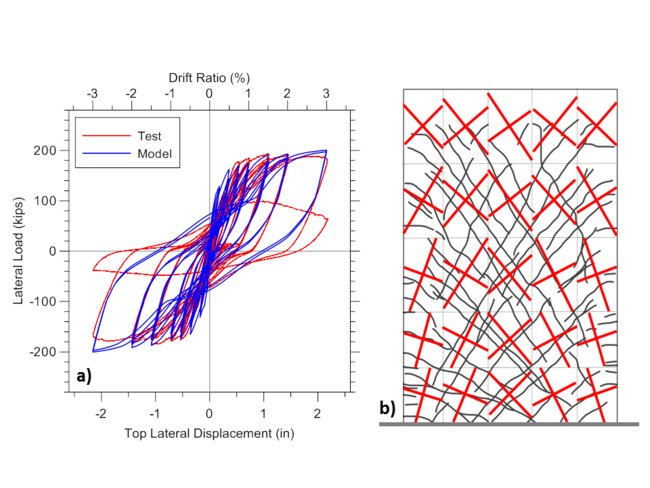

E.3.1. Global Wall Responses

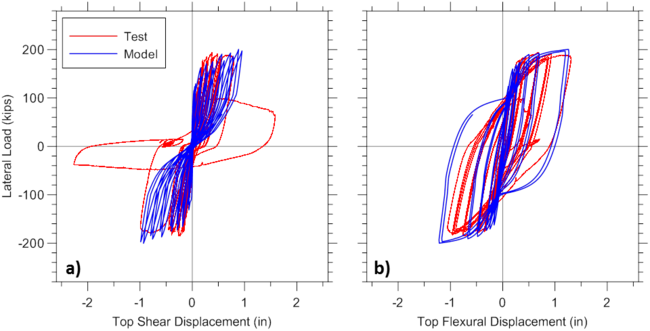

Analytical and experimental lateral load versus top total displacement responses and wall cracking patterns are presented on Figure E1.2, whereas lateral load versus flexural and shear deformations are shown on Figure E1.3. Total top displacement is obtained from the top node, shear force is recorded using globalForce element recorder, total shear displacement is obtained using shearDef element recorder and crack orientations are obtained using RCPanel and cracking_angles element recorders.

E.3.2. Model Element Responses

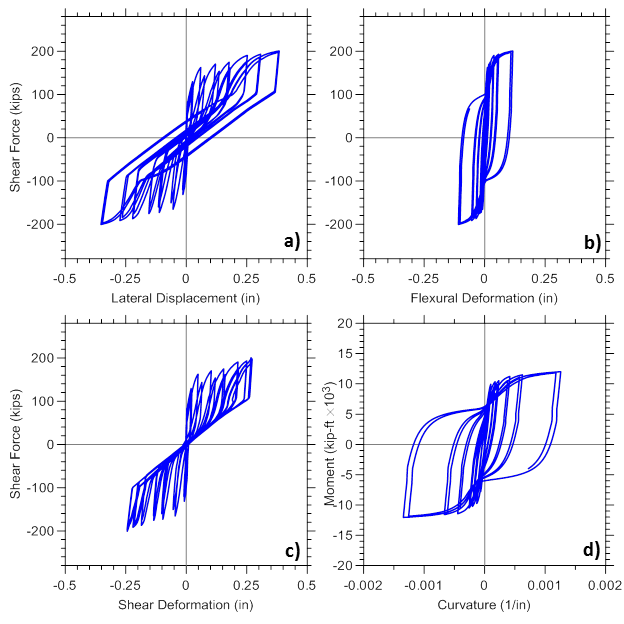

Figure E1.4 plots lateral load versus total, flexural and shear displacement responses, as well as moment versus curvature relationship, obtained from the analysis for the bottom wall model element. Responses are recorded using globalForce, ShearDef, and Curvature element recorders.

E.3.3. Reinforced Concrete Panel Responses

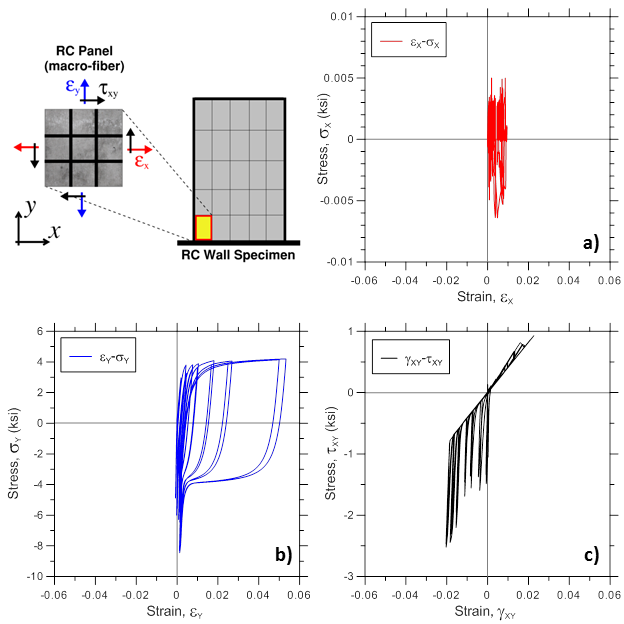

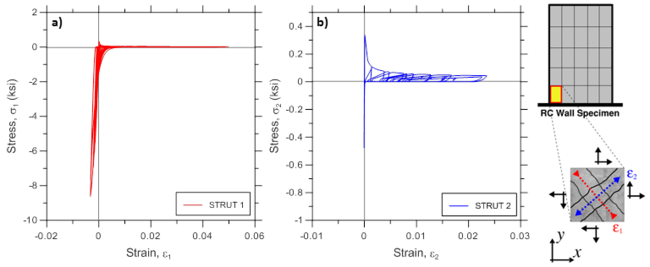

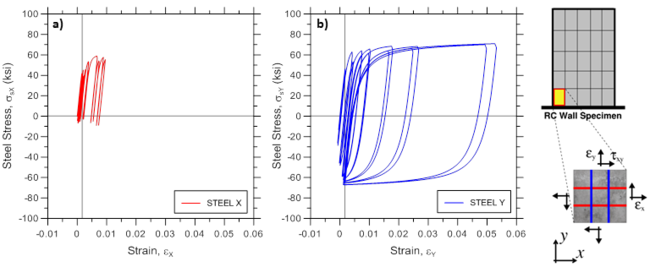

Various stress-strain responses for an individual boundary panel element (outermost macro-fiber) within the bottommost wall element (Figure E1.5) are presented, including total (resultant) stress vs. strain relationships in the xy plane (Figure E1.5; element RCPanel recorders: panel_strain and panel_stress), stress-strain relationships along the two concrete struts (Figure E1.6; element RCPanel recorders: strain_stress_concrete1 and strain_stress_concrete2), and stress-strain relationship along horizontal and vertical steel reinforcement (Figure E1.7; element RCPanel recorders: strain_stress_steelX and strain_stress_steelY).

uniaxialMaterial SteelMPF

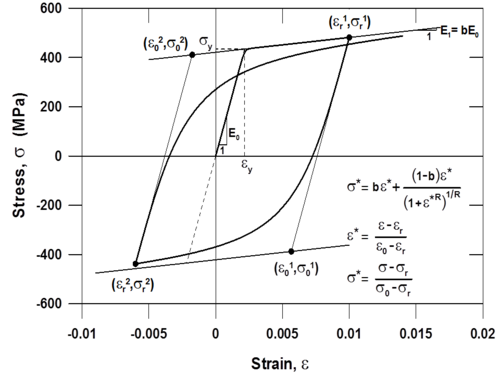

This command is used to construct a uniaxialMaterial SteelMPF, which represents the well-known uniaxial constitutive nonlinear hysteretic material model for steel proposed by Menegotto and Pinto (1973), and extended by Filippou et al. (1983) to include isotropic strain hardening effects. The relationship is in the form of curved transitions (Figure 1), each from a straight-line asymptote with slope E0 (modulus of elasticity) to another straight-line asymptote with slope E1 = bE0 (yield modulus) where b is the strain hardening ratio. The curvature of the transition curve between the two asymptotes is governed by a cyclic curvature parameter R, which permits the Bauschinger effect to be represented, and is dependent on the absolute strain difference between the current asymptote intersection point and the previous maximum or minimum strain reversal point depending on whether the current strain is increasing or decreasing, respectively. The strain and stress pairs (<math>\epsilon</math>r,<math>\sigma</math>r) and (<math>\epsilon</math>0,<math>\sigma</math>0) shown on Figure 1 are updated after each strain reversal.

Source: /usr/local/cvs/OpenSees/SRC/material/uniaxial/

Input Format:

| uniaxialMaterial SteelMPF $mattag $fyp $fyn $E0 $bp $bn $R0 $a1 $a2 <$a3 $a4> |

| $mattag | Unique uniaxialMaterial tag |

| $fyp | Yield strength in tension (positive loading direction) |

| $fyn | Yield strength in compression (negative loading direction) |

| $E0 | Initial tangent modulus |

| $bp | Strain hardening ratio in tension (positive loading direction) |

| $bn | Strain hardening ratio in compression (negative loading direction) |

| $R0 | Initial value of the curvature parameter R (R0 = 20 recommended) |

| $a1 | Curvature degradation parameter (a1 = 18.5 recommended) |

| $a2 | Curvature degradation parameter (a2 = 0.15 or 0.0015 recommended) |

| $a3 | Isotropic hardening parameter (optional, default = 0.01) |

| $a4 | Isotropic hardening parameter (optional, default = 7.0) |

Example:

uniaxialMaterial SteelMPF 1 60 60 29000 0.02 0.02 20.0 18.5 0.15

Discussion:

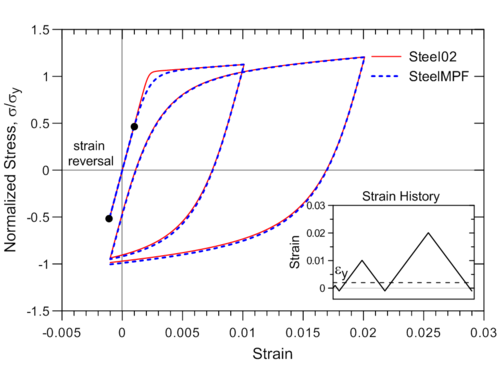

Although the Menegotto-Pinto model is already available in OpenSees (e.g., Steel02), the formulation of SteelMPF brings several distinctive features compared to existing models. For example, the model allows definition of different yield stress values and strain hardening ratios for tension and compression, and it considers degradation of cyclic curvature parameter R for strain reversals in both pre- and post- yielding regions, which could produce more accurate predictions of yield capacity for some RC wall specimens (see Example 1), whereas Steel02 considers the degradation in post-yielding region only. Strain-stress relationships obtained using SteelMPF and Steel02 are compared in Figure 2 for a strain history that includes strain reversals at strain values equal to one-half of the yield strain (e.i., <math>\epsilon</math>r = ±0.001 = <math>\epsilon</math>y/2). The model also allows calibration of isotropic hardening parameters through optional input variables a3 and a4, and uses default values of a3 = 0.01 and a4 = 7.0 as calibrated by Filippou et al. (1983) based on test results. To disregard isotropic strain hardening behavior in SteelMPF, parameter a3 needs to be assigned a zero value (a3 = 0.0).

References:

Developed and Implemented by:

Kristijan Kolozvari, California State University Fullerton

Kutay Orakcal, Bogazici University, Istanbul, Turkey

John Wallace, Univeristy of California, Los Angeles

1) Filippou F.C., Popov, E.P., and Bertero, V.V. (1983). "Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints". Report EERC 83-19, Earthquake Engineering Research Center, University of California, Berkeley.

2) Menegotto, M., and Pinto, P.E. (1973). Method of analysis of cyclically loaded RC plane frames including changes in geometry and non-elastic behavior of elements under normal force and bending. Preliminary Report IABSE, vol 13.

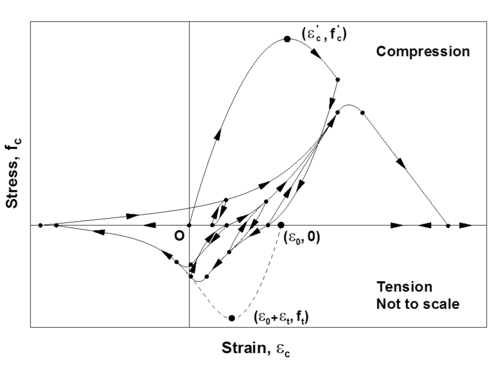

uniaxialMaterial ConcreteCM

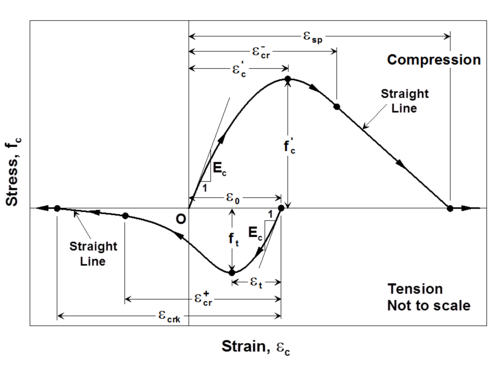

This command is used to construct a uniaxialMaterial ConcreteCM, which is a uniaxial hysteretic constitutive model for concrete developed by Chang and Mander (1994). This model is a refined, rule-based, generalized, and non-dimensional constitutive model that allows calibration of the monotonic and hysteretic material modeling parameters, and can simulate the hysteretic behavior of confined and unconfined, ordinary and high-strength concrete, in both cyclic compression and tension (Figure 1). The model addresses important behavioral features, such as continuous hysteretic behavior under cyclic compression and tension, progressive stiffness degradation associated with smooth unloading and reloading curves at increasing strain values, and gradual crack closure effects. Details of the model are available in the report by Chang and Mander (1994). Note that ConcreteCM incorporates the unloading/reloading rules defined originally by Chang and Mander (1994), as opposed to Concrete07, which adopts simplified hysteretic rules.

The Chang and Mander (1994) model successfully generates continuous hysteretic stress-strain relationships with slope continuity for confined and unconfined concrete in both compression and tension. The compression envelope curve of the model is defined by the initial tangent slope, (Ec), the peak coordinate (epcc, fpcc), a parameter (rc) from Tsai’s (1988) equation defining the shape of the envelope curve, and a parameter (xcrn) to define normalized (with respect to epcc) strain where the envelope curve starts following a straight line, until zero compressive stress is reached at the spalling strain, <math>\epsilon</math>sp. These parameters can be controlled based on specific experimental results for a refined calibration of the compression envelope (Figure 2). Chang and Mander (1994) proposed empirical relationships for parameters Ec, epcc, and rc for unconfined concrete with compressive strength fpcc, based on review of previous research. Parameters fpcc, epcc, Ec, rc, and xcrn can also be calibrated to represent the stress-strain behavior of confined concrete in compression, to follow the constitutive relationships for confined concrete proposed by Mander et al (1988) or similar.

The shape of the tension envelope curve in the model is the same as that of the compression envelope; however, the tension envelope curve is shifted to a new origin that is based on the unloading strain from the compression envelope (Figure 2). As well, the strain ductility experienced previously on the compression envelope is also reflected on the tension envelope. The parameters associated with the tension envelope curve include the tensile strength of concrete (ft), the monotonic strain at tensile strength (et), a parameter (rt) from Tsai’s (1988) equation defining the shape of the tension envelope curve, and a parameter (xcrp) to define normalized (with respect to et) strain where the tension envelope curve starts following a straight line, until zero tensile stress is reached at a strain of <math>\epsilon</math>crk. These parameters can also be controlled and calibrated based on specific experimental results or empirical relations proposed by other researchers (e.g., Belarbi and Hsu, 1994) to model the behavior of concrete in tension and the tension stiffening phenomenon. Concrete experiencing tension stiffening can be considered not to crack completely; that is, a large value for parameter xcrp (e.g., 10000) can be defined.

Source: /usr/local/cvs/OpenSees/SRC/material/uniaxial/

Input Format:

| uniaxialMaterial ConcreteCM $mattag $fpcc $epcc $Ec $rc $xcrn $ft $et $rt $xcrp <-GapClose $gap> |

| $mattag | Unique uniaxialMaterial tag |

| $fpcc | Compressive strength |

| $epcc | Strain at compressive strength |

| $Ec | Initial tangent modulus |

| $rc | Shape parameter in Tsai’s equation defined for compression |

| $xcrn | Non-dimensional critical strain on compression envelope (where the envelope curve starts following a straight line) |

| $ft | Tensile strength |

| $rt | Shape parameter in Tsai’s equation defined for tension |

| $xcrp | Non-dimensional critical strain on tension envelope (where the envelope curve starts following a straight line – large value [e.g., 10000] recommended when tension stiffening is considered) |

| <-GapClose $gap> | gap = 0, less gradual gap closure (default); gap = 1, more gradual gap closure |

Example:

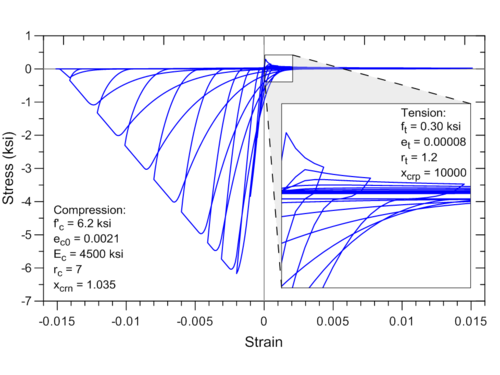

uniaxialMaterial ConcreteCM 1 -6.2 -0.0021 4500 7 1.035 0.30 0.00008 1.2 10000

Example of hysteretic stress–strain history generated by the model code is illustrated in Figure 3.

Discussion:

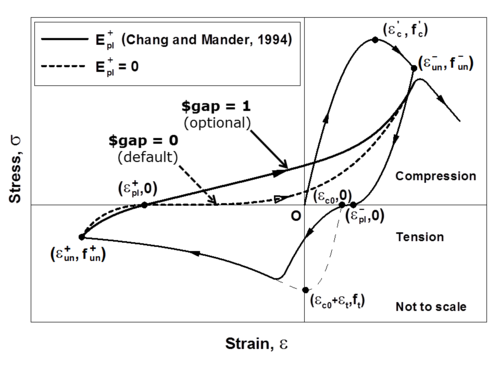

An optional input parameter gap is introduced in the ConcreteCM model implemented in OpenSees for providing the users with the opportunity to control the intensity of gap closure in the stress-strain behavior of concrete, which in-turn influences the level of pinching in the lateral load-displacement behavior of a RC wall. The original Chang and Mander (1994) model adopts a non-zero tangent stiffness at zero stress level upon unloading from the tension envelope, which is represented by gap = 1 in ConcreteCM. Using gap = 0 (default) produces less gradual gap closure, since it assumes zero tangent stiffness at zero stress level upon unloading from the tension envelope, and is suitable for most analyses. Figure 4 illustrates the effect of plastic stiffness upon unloading from tension envelope (Epl+) on crack closure, i.e. use of more gradual (gap = 1) or less gradual (gap = 0) gap closure.

References:

Developed and Implemented by:

Kristijan Kolozvari, California State University Fullerton

Kutay Orakcal, Bogazici University, Istanbul, Turkey

John Wallace, Univeristy of California, Los Angeles

1) Belarbi H. and Hsu T.C.C. (1994). “Constitutive Laws of Concrete in Tension and Reinforcing Bars Stiffened by Concrete”, ACI Structural Journal, V. 91, No. 4, pp. 465-474.

2) Chang, G.A. and Mander, J.B. (1994), “Seismic Energy Based Fatigue Damage Analysis of Bridge Columns: Part I – Evaluation of Seismic Capacity”, NCEER Technical Report No. NCEER-94-0006, State University of New York, Buffalo.

3) Mander J.B., Priestley M.J.N., and Park R. (1988). “Theoretical Stress-Strain Model for Confined Concrete”, ASCE Journal of Structural Engineering, V. 114, No. 8, pp. 1804-1826.

4) Orakcal K.(2004), "Nonlinear Modeling and Analysis of Slender Reinforced Concrete Walls", PhD Dissertation, Department of Civil and Environmental Engineering, University of California, Los Angeles.

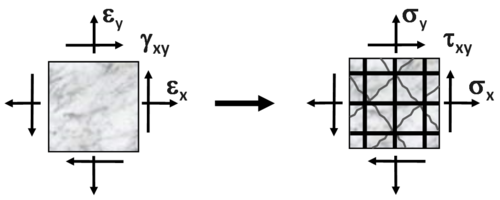

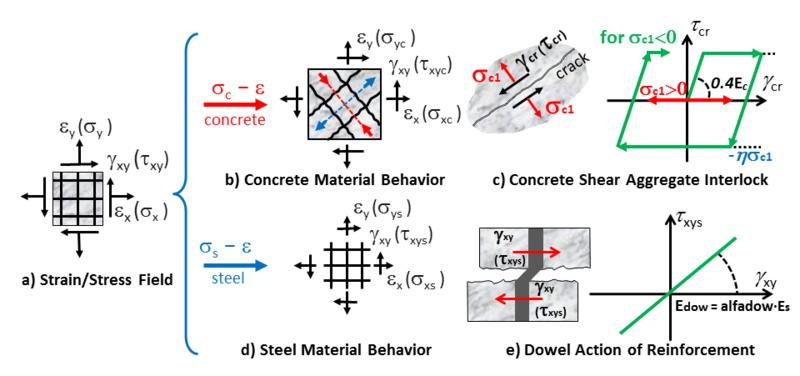

NDMaterial FSAM

This command is used to construct a nDMaterial FSAM (Fixed-Strut-Angle-Model, Figure 1), which is a plane-stress constitutive model for simulating the behavior of RC panel elements under generalized, in-plane, reversed-cyclic loading conditions (Ulugtekin, 2010; Orakcal et al., 2012). In the FSAM constitutive model, the strain fields acting on concrete and reinforcing steel components of a RC panel are assumed to be equal to each other, implying perfect bond assumption between concrete and reinforcing steel bars. While the reinforcing steel bars develop uniaxial stresses under strains in their longitudinal direction, the behavior of concrete is defined using stress–strain relationships in biaxial directions, the orientation of which is governed by the state of cracking in concrete. Although the concrete stress–strain relationship used in the FSAM is fundamentally uniaxial in nature, it also incorporates biaxial softening effects including compression softening and biaxial damage. For transfer of shear stresses across the cracks, a friction-based elasto-plastic shear aggregate interlock model is adopted, together with a linear elastic model for representing dowel action on the reinforcing steel bars (Kolozvari, 2013).

Source: /usr/local/cvs/OpenSees/SRC/material/nD/reinforcedConcretePlaneStress/

Input Format:

| nDMaterial FSAM $mattag $rho $sX $sY $conc $rouX $rouY $nu $alfadow |

| $mattag | Unique nDMaterial tag |

| $rho | Material density |

| $sX | Tag of uniaxialMaterial simulating horizontal (-X) reinforcement |

| $sY | Tag of uniaxialMaterial simulating vertical (-Y) reinforcement |

| $conc | Tag of uniaxialMaterial1 simulating concrete |

| $rouX | Reinforcing ratio in horizontal (-X) direction (rouX = AsX/AgrossX) |

| $rouY | Reinforcing ratio in vertical (-Y) direction (rouY = AsY/AgrossY) |

| $nu | Concrete friction coefficient (0.0 < $nu < 1.5) |

| $alfadow | Stiffness coefficient of reinf. dowel action (0.0 < $alfadow < 0.05) |

1nDMaterial FSAM shall be used with uniaxialMaterial ConcreteCM

Recommended values for parameter of a shear resisting mechanism (nu and alfadow, Figure 2) are provided above. Details about the sensitivity of analytical predictions using SFI_MVLEM to changes in these parameters are presented by Kolozvari (2013).

Material Recorders:

The following output is available from the FSAM RC panel model:

| panel_strain | Strains <math>\epsilon</math>x, <math>\epsilon</math>y, <math>\epsilon</math>xy (Figure 4) |

| panel_stress | Resulting panel stresses <math>\epsilon</math>x, <math>\epsilon</math>y, <math>\tau</math>xy (concrete and steel, Figure 1) |

| panel_stress_concrete | Resulting panel concrete stresses xc, yc, xyc (Figure 2b) |

| panel_stress_steel | Resulting panel steel stresses xs, ys, xys (Figure 2d) |

| strain_stress_steelX | Uniaxial strain and stress of horizontal reinforcement x, xxs |

| strain_stress_steelY | Uniaxial strain and stress of vertical reinforcement y, yys |

| strain_stress_concrete1 | Uniaxial strain and stress of concrete strut 1 c1, c1 |

| strain_stress_concrete2 | Uniaxial strain and stress of concrete strut 2 c2, c2 |

| strain_stress_interlock1 | Shear strain and stress in concrete along crack 1 cr1, cr1 (Figure 2c) |

| strain_stress_interlock2 | Shear strain and stress in concrete along crack 2 cr2, cr2 (Figure 2c) |

| cracking_angles | Orientation of concrete cracks |

Note that recorders for a RC panel (marco-fiber) are invoked as SFI_MVLEM element recorders using command RCPanel and one of the desired commands listed above. Currently, it is possible to output values only for one macro-fiber within one or multiple elements.

Example:

nDMaterial FSAM 1 0.0 1 2 4 0.0073 0.0606 0.1 0.01

Recorder Element -file MVLEM_panel_strain.out -time -ele 1 RCPanel 1 panel_strain

References:

Developed and Implemented by:

Kristijan Kolozvari, California State University Fullerton

Kutay Orakcal, Bogazici University, Istanbul, Turkey

John Wallace, Univeristy of California, Los Angeles

1) Kolozvari K. (2013). “Analytical Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls”, PhD Dissertation, University of California, Los Angeles.

2) Orakcal K., Massone L.M., and Ulugtekin D. (2012). “Constitutive Modeling of Reinforced Concrete Panel Behavior under Cyclic Loading”, Proceedings, 15th World Conference on Earthquake Engineering, Lisbon, Portugal.

3) Ulugtekin D. (2010). “Analytical Modeling of Reinforced Concrete Panel Elements under Reversed Cyclic Loadings”, M.S. Thesis, Bogazici University, Istanbul, Turkey.